hardness test rb|steel hardness chart : store Rockwell C to Brinell Hardness Conversion Chart. While the Rockwell hardness testing scale is prevalent, it is best to consider the material thickness and softness to select . 26 de jan. de 2024 · Sobre o jogo. O (A) Deportivo Pasto enfrentará o (a) Deportes Tolima a 26/01/2024, às 23:10 (hora UTC) no Estadio Departamental Libertad, Pasto, Colombia. O jogo realiza-se para a (o) Primera A, Apertura. Atualmente, o (a) Deportivo Pasto está em 15.º, sendo que o (a) Deportes Tolima está em 14.º lugar. Queres comparar o jogador .

{plog:ftitle_list}

webMinha Conta; X. ACOMPANHE-NOS NAS REDES SOCIAIS. Facebook; Instagram; Twitter; Linkedin; Jogos. Ragnarök; Perfect World; Suporte. . Interactive Ltda. TODOS OS DIREITOS RESERVADOS A Level Up respeita a sua privacidade! Se você tem alguma dúvida sobre como realizamos a proteção dos seus dados, entre em contato com a .

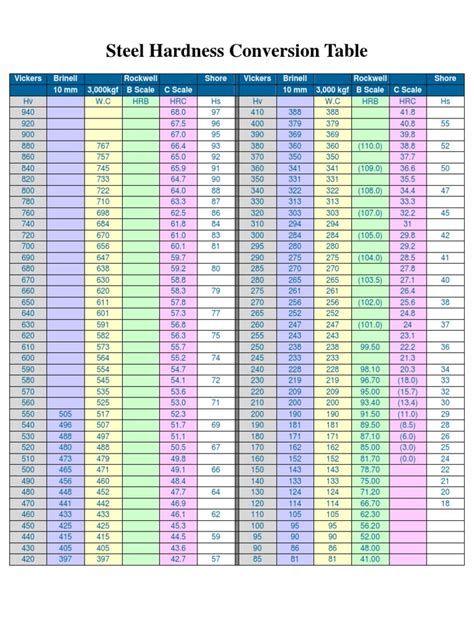

Brinell and Rockwell Hardness Conversion Chart - These Conversion Tables . The most common is the static load indentation hardness test, such as Brinell Hardness (HB), Rockwell Hardness (HRA, HRB, HRC), and Vickers Hardness (HV). These hardness values indicate the ability of a .

Rockwell C to Brinell Hardness Conversion Chart. While the Rockwell hardness testing scale is prevalent, it is best to consider the material thickness and softness to select .The Rockwell hardness test is categorized into three types: Regular Rockwell hardness test: In this test, a load of 60, 100, or 150 kg is applied to the surface of the material for a few seconds, depending on the hardness of the material. This table shows approximate hardness of steel using Brinell, Rockwell B and C and Vickers scales. These conversion charts are provided for guidance only as each scales uses .

This hardness conversion calculator will convert hardness numbers between the Brinell, Rockwell, and Vickers hardness scales.The table below converts Brinell Hardness to Rockwell Hardness scales and vice versa, then compares those to the approximate tensile strength that those scales indicate.

Bench Hardness Testers. Refurbished; Hardness Tester Accessories. Rockwell Ball Penetrators; Diamond Indenters . Rockwell Indenters; Knoop Indenters; Vickers Indenters; Anvils; Test Blocks. Knoop Test Blocks; Vickers Test .

Hardness Conversion Formula. Y = aX^2 + bX + c. Where: Y is the hardness value in the target scale; X is the hardness value in the original scale; a, b, and c are constants determined through empirical testing; Example: Converting Brinell (HB) to Rockwell C (HRC) for steels:. HRC = -0.000000567 HB^2 + 0.0624 HB – 13.7. Using this formula, we can convert a Brinell hardness .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as . The hardness of steel depends on several factors, such as its composition, manufacturing, and heat-treating processes.The different hardness scales use different loads, different indentor shapes, and different measurements to obtain the hardness number. There are no straightforward formulae to establish relationships between the different scales, making .

Minimum of two test blocks with at least one test block for each scale to be verified. At least two of the test blocks shall be from different hardness ranges. The difference between two blocks shall be a minimum of 100 points. The highest test force shall be verified on a block from the lower hardness range to product the largest indentation size.

A variety of hardness-testing methods are available, including the Vickers, Brinell, Rockwell, Meyer and Leeb tests. Although it is impossible in many cases to give an exact conversion, it is possible to give an approximate material-specific comparison table for steels. Hardness comparison table.The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the .Rockwell Hardness (HRC, HRB) to Brinell Hardness (HB or BHN) Conversion. Hardness is very important for producing rough metal castings, heat treatment and machining process. Rockwell Hardness (HRC and HRB) and Brinell Hardness (HB or BHN) are most commonly used for steel and iron castings. Reaction-bonded silicon carbide (RB-SiC), as one of the most prosperous material for substrate of lightweight space optical mirrors [1], [2], is very difficult to machine because of its high hardness and brittleness.In recent years, some thermal-involved hybrid processes, such as laser assisted machining [3], [4], [5], ultrasonic assisted electrical discharge machining [6], [7], .

It is impossible to define a single conversion method using different hardness test methods. That’s why these standards formulate tables for conversion process, with test load and hardness ranges. Here are the hardness tables and conversion charts for you. + 86 755 61301520; [email protected]; Search. Home; About Us.

A key component of Brinell hardness testers, these ball indenters are hard enough to make impressions on most metal. Made of carbide, they won’t deform as they press into hard material. Shallow indentations mean a material is hard and deep indentations show that it is soft. Use the diameter of the indentations created by these balls as part of the calculation to find your . In this paper, mechanical properties of RB-SiC ceramics, such as hardness, elastic modulus and fracture toughness, are characterized through indentation technique using a Vickers indenter at elevated temperatures ranging from room temperature to1200 °C realized by laser heating. The indentation size effect, load-displacement curves and relationship between .Standard Brinell hardness test: In this test, a load of 500 to 3000 kg is applied to the surface of the material for 10 to 30 seconds, depending on the hardness of the material. Micro Brinell hardness test: In this test, a load of less than 1 kg is applied to the surface of the material for a longer duration, typically 15 to 60 seconds.

The Brinell hardness test consists in indenting the metal surface with a 10-mm-diameter steel ball at a load of 3,000 kg mass (∼29400 N). . The range of this scale is from RB 0 to RB 100. The A scale (diamond penetrator, 60-kg major load) provides the most extended Rockwell hardness scale, which is usable for materials from annealed brass .

International Standards Organization – Rockwell Hardness Test Part 1 – Test Method (ISO 6508-1 Metallic Materials) The reason all steel product manufacturers use the Rockwell hardness scale is that it allows uniformity in .

RB 100 1/16” RC 150 Brale RD 100 Brale . Hardness test methods. Fracture Toughness. Fatigue. Creep. Chemical Composition Evaluation. Adhesion tests. Metallographic examination. Plastic deformation. Hardness tests of ceramics. to Metals to Metal properties and tests. hardness_conversion_table.txt Vickers hardness test is a micro testing method used for some specified cases. Sometimes it becomes necessary to change the hardness value from one scale to another. Here we compare the Vickers hardness method with the Rockwell method and their conversion charts. + 86 755 61301520; [email protected]; Search. Home; The calculator has two modes — calculate and convert.The calculate mode is helpful if you have the indentation depth and want the Rockwell hardness number for either scale B or C. The convert mode is for converting Rockwell hardness numbers to a different scale like Brinell or Vickers.. The hardness data can not be presented in terms of a universal conversion .

The Rockwell Hardness test also uses a machine to apply a specific load and then measure the depth of the resulting impression. Rockwell hardness number can be represented by HRB. When the material is very thin, lighter loads must be used, resulting in Rockwell 30T. The test measures the hardness by pressing an indentor into the surface of the .1018 1020 1021 1026 1029 1030 1035 1040 1045 1050 1055 1060 1065 1070 1080 1117 1141 1146 ABS Grade 2 A-105 15B22 MOD 1545 A350 LF2; 0.15-0.20: 0.18-0.23: 0.18-0.23: 0.22-0.28 To obtain the best results, you should be aware of any special techniques that can be used to improve the test method. Rockwell Hardness Testing. Because of its low force, high speed, and nondestructive nature, Rockwell hardness testing commonly is used on all sizes of tubing. To perform a Rockwell test successfully, you must consider several .

Hardness Conversion per ASTM E-140, Strength per ASTM A370, See bottom half of table. Hardness Conversion Table Brinell Hardness HB 10/3000/15 Rockwell Hardness Superficial Hardness Approx Tensile Dia (mm) HB A 60kg B 100kg C 150kg 15T 15kg 30T 30kg 45T 45kg (KSI) 5.30 126 44.5 70.5 -- 83.5 63.5 43.5 61 RB 100 1/16” RC 150 Brale RD 100 Brale . Hardness test methods. Fracture Toughness. Fatigue. Creep. Chemical Composition Evaluation. Adhesion tests. Metallographic examination. Plastic deformation. Hardness tests of ceramics. to Metals to Metal properties and tests. hardness_conversion_table.txt A comprehensive variety of scales and hardness test blocks are available to meet the wide ranges and hardness scales associated with Rockwell®, Brinell, Knoop and Vickers testing. All Wilson Rockwell hardness test blocks are calibrated in the Wilson Hardness Calibration Laboratory in Binghamton, NY. The Wilson lab is accredited to ISO/IEC .

steel hardness conversion chart

You can use the Rockwell hardness test to test the hardness of materials. You will use the Rockwell test to perform tests on metals ranging from thin steel all the way to harder metals like Titanium. However, there are multiple scales to test in and these are identified by a letter ranging from A-V Each scale uses a different indenter and load to perform the test.

A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

lenovo hard drive test software

lenovo hard drive test tool

Check out the Watch ESPN schedule of live streaming games and programming happening right now, upcoming shows and replays.

hardness test rb|steel hardness chart